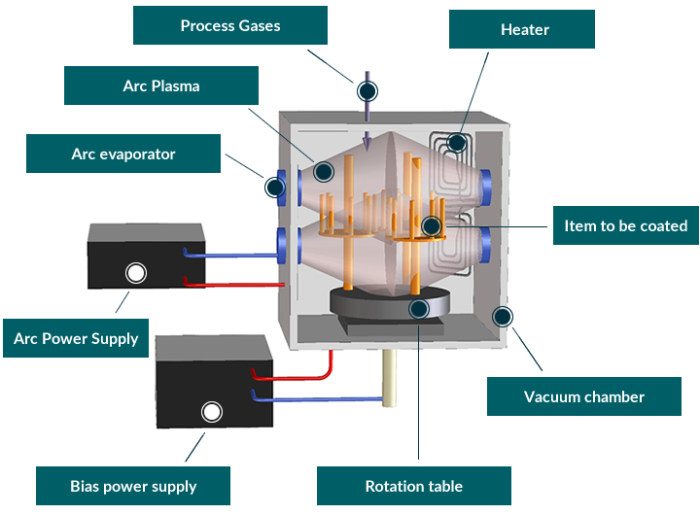

Arc evaporation

Arc evaporation is a way of physical vapor deposition. The application of PVD in hard coating starts from the arc technology. The arc technology originated from electric welding. The evaporated solid metal (target) is placed in the vacuum chamber to generate glow discharge, and then it runs on the target surface. The target evaporates in a very small range, about several microns in size. The arc motion is controlled by the magnetic field. The plasma formed by the evaporated metal ions will be deposited on the surface of the workpiece. These workpieces rotate in the vacuum cavity. The coating prepared by the arc is usually used for the surface coating of tools and parts, such as tin, AlTiN, AlCrN, TiSiN, TiCN, crcn and CrN. The evaporated metal is ionized and accelerated into the electric field at the same time. In the arc process, the evaporated material is highly ionized, and the deposited coating has excellent adhesion.

Advantages of arc technology:

+High deposition rate (~ 1-3 μ M / h)

+High dissociation rate, good adhesion and compact coating

+When the target is cooled, the coated workpiece is heated less, so that it can be deposited below 100 ° C

+Metals with multiple components can be evaporated, and the remaining solid target components remain unchanged

+The cathode can be placed in any position (horizontal, vertical, upper and lower), and the equipment design is flexible

Main disadvantages of arc technology:

− Limited target material

−Only metals (excluding oxides) can be used, so that the evaporation temperature will not be low

−Due to the high current density, some target materials are splashed out by evaporation in the form of small droplets